Pricing shisha products may appear complex, but it relies on understanding key cost foundations. For moassel producers, pricing closely connects to shisha tobacco and flavor development decisions.

Every pricing strategy starts with analyzing ingredients that directly shape quality and consistency. The two main cost drivers are flavors, also called essences, and tobacco. By managing these carefully, producers can achieve competitive, profitable, and sustainable pricing.

The Role of Shisha Flavors and Tobacco in Pricing

Flavors and tobacco form the core of every shisha product’s value and cost structure. They define production expenses, sensory quality, and brand positioning simultaneously.

Because both elements influence consumer perception, they directly impact acceptable market pricing. Understanding their role helps producers build realistic and scalable pricing strategies.

Why Shisha Flavors Affect Pricing

Natural vs. synthetic shisha flavors

Flavors strongly influence pricing because they directly affect both production costs and perceived value. Natural flavors usually cost more due to complex extraction, agricultural sourcing, and seasonal availability. These factors increase raw material expenses and supply uncertainty. As a result, products using natural flavors often require higher pricing to protect margins.

In contrast, synthetic flavors offer greater stability, consistent quality, and lower costs. They allow easier cost control and scalable production planning. However, synthetic options may limit premium brand positioning for some markets. Choosing between natural and synthetic flavors directly impacts pricing strategy and customer perception.

Simple vs. complex blends

Simple flavor blends require fewer raw materials and shorter development time. Complex blends involve multiple notes, testing cycles, and formulation expertise. As complexity increases, flavor development costs rise accordingly.

Popular vs. rare shisha flavors

Popular flavors benefit from stable demand and predictable sourcing costs. In contrast, rare flavors often require special ingredients and rely on limited suppliers. As a result, this scarcity naturally increases formulation and pricing complexity.

Why Tobacco Quality Matters

Premium vs. standard tobacco

Premium tobacco undergoes stricter leaf selection, curing, and processing methods. These steps increase raw material costs but improve consistency and performance. As a result, premium tobacco supports higher price positioning.

Standard tobacco lowers costs through simplified processing and wider sourcing options. However, it may introduce variations in texture, burn rate, or moisture. This inconsistency can limit pricing flexibility in competitive markets.

Impact on taste and customer perception

High-quality tobacco enhances flavor clarity and overall smoking smoothness. It allows flavors to perform as intended without harsh or bitter notes. This improves the overall sensory experience.

Consumers often associate smoother smoke with superior product quality. Strong perception increases brand trust and repeat purchases. Willingness to pay rises when taste meets expectations.

Balancing quality and cost

Producers must align tobacco quality with their target market and price segment. Otherwise, using premium tobacco for mass-market products may reduce profitability. Therefore, cost efficiency remains essential for long-term sustainability. In this regard, strategic blending and sourcing help balance quality and cost effectively. Smart decisions protect margins while meeting customer expectations. This balance supports stable growth and competitive pricing.

Materials and Ingredients: The Starting Point for Pricing shisha Flavors in the Shisha Industry

Ingredient sourcing decisions strongly influence cost stability and production scalability. Reliable suppliers reduce supply risks and quality variations. However, trusted sources may charge higher unit prices.

Strategic sourcing creates predictable cost structures and long-term planning confidence. It allows producers to manage margins more effectively. Strong sourcing strategies support sustainable pricing models.

In-house production vs. purchasing from suppliers

In-house flavor production offers greater control over formulation and quality consistency. It allows faster adjustments and unique flavor development. However, it requires significant investment in equipment and expertise.

Purchasing flavors from external suppliers reduces operational complexity and fixed costs. It simplifies scaling and production planning. However, limited customization may affect product differentiation and pricing flexibility.

Cost differences between natural and synthetic shisha flavors

Natural flavors require higher investment due to farming, extraction, and seasonal availability. Agricultural variability increases price fluctuations and sourcing risks. These factors complicate long-term cost forecasting.

Synthetic flavors offer consistent pricing and reliable availability throughout the year. They support stable production planning and cost control. This consistency benefits scalable pricing strategies.

How shisha flavor sourcing affects the final product price

Flavor sourcing directly defines formulation cost and batch consistency. Stable suppliers support predictable production expenses. This stability allows confident pricing decisions.

Unstable sourcing introduces cost fluctuations and supply interruptions. These risks increase buffer costs and pricing uncertainty. As a result, final product prices may become less competitive.

H2. Production and Supply Chain Factors

Beyond ingredients, production and logistics significantly influence pricing outcomes. Labor, packaging, and transportation add layered costs. Ignoring these factors weakens pricing accuracy.

Manufacturing and Labor Costs

How complexity of production adds to costs

Complex production processes require skilled labor and specialized equipment. Each additional step increases time, supervision, and operational effort. These factors raise overall manufacturing expenses.

Longer production cycles reduce throughput and increase labor intensity. More quality checks also add indirect costs. Production efficiency therefore plays a critical role in final pricing.

In-house production vs. outsourcing

In-house production improves control over quality, scheduling, and confidentiality. However, it increases fixed costs such as salaries, maintenance, and utilities. These expenses raise the cost base.

Outsourcing reduces overhead and allows flexible production scaling. It converts fixed costs into variable expenses. However, reduced control may affect consistency and long-term pricing strategy.

Packaging and Distribution

Premium packaging costs vs. standard

Premium packaging enhances brand perception but raises unit costs. Standard packaging supports competitive pricing. Packaging choice affects positioning.

Shipping, taxes, and regulations affecting final price

Logistics costs vary by region and regulatory requirements. Taxes and compliance fees add hidden expenses. These must be included in pricing.

How to Set Prices for Shisha Products

Setting prices for shisha products requires a structured and cost-driven approach. To achieve this, moassel producers must account for ingredients, production, and market positioning. As a result, a clear process reduces risk and supports consistent profitability.

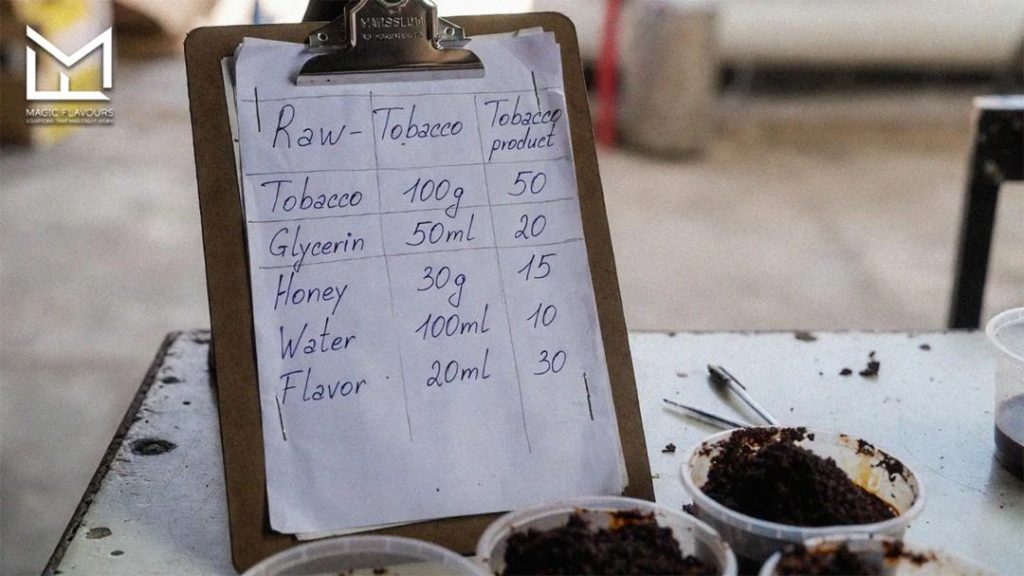

1. Calculate ingredient costs – flavors and tobacco

Start by calculating the exact cost of flavors and tobacco per production batch. Include sourcing, transportation, and waste considerations. Accurate ingredient costing creates a reliable pricing foundation.

2. Add production and packaging costs

Next, include manufacturing labor, utilities, and quality control expenses. Packaging materials and labeling must also be counted. These costs significantly influence the final unit price.

3. Include distribution, logistics, and taxes

Distribution costs typically include shipping, storage, and handling fees. In addition, taxes and regulatory charges must be added accurately. Otherwise, ignoring these costs can quickly reduce profit margins.

4. Adjust for market positioning – premium vs. affordable

Finally, adjust pricing based on brand positioning and target customers. Premium products allow higher margins through perceived value. Affordable products require tighter cost control to remain competitive.

Final Thoughts

Effective pricing, however, requires a deep understanding of flavors and tobacco economics. Therefore, strategic decisions not only protect margins but also strengthen brand credibility. In this context, Magic Flavours supports moassel producers by offering expert consultation on flavor sourcing, development, and well-informed pricing strategies.